The screw press consists of drainage area, supply area, screw conveying area and supply area. Fence slag enters the material area. After the pressure in the pressure zone, the fence slag is discharged with a screw press, and the waste liquid flows from the fence into the water collection pipe. 1. The screw press machine runs slowly under normal conditions without damage. If the expected dehydration effect is not achieved, as long as the large-capacity capacitor is replaced, the capacitance of the device will be very small. 2. If the equipment can operate normally after purchase, but cannot run quickly after using for a period of time, the possibility of leakage after the capacitor enters the water is high, just replace it with a new capacitor of the same type. 3. Another reason is that the main shaft of the equipment is too loose or the main shaft brake is too tight, which can be solved by tightening or readjusting the brake iron plate.

The advantages of the screw press: 1. The contact area with the material is small, which can effectively improve the extrusion efficiency;

2. The design of the equipment is reasonable, and it will not be blocked during use;

3. The stainless steel profile has good durability, good wear resistance and long service life;

4. The fruit and vegetable press is directly driven by the shaft, and the operation has relatively low energy consumption, which is an energy-saving product;

5. Set a spring baffle at the discharge port to increase the dehydration effect and make the book support effect close to the ideal value;

6. The discharge port adopts a sealed design, which does not protect the product, does not pollute the surrounding environment, and keeps the environment clean and hygienic.

What should I pay attention to when buying a screw press?

When purchasing, we need to understand the materials that need to be processed. There are also different expellers with different fiber content. For example, for materials with high fiber content, such as ginger and sawdust, we need to choose a double-screw press. When the fiber content is low, such as mulberries and apples, we need to choose a single screw press.

A screw press is a machine that squeezes liquid out of material by the pressure of a dehydrating screw, operating in a continuous (not batch process) manner. Screw presses can be used for various liquid-solid separations. Independently driven rotors and adjustable cone sections provide instant pressure adjustment and proper extrusion. The press machine produced by our company adopts a comprehensive design, which can combine size reduction with solid-liquid separation, without transportation, and has the characteristics of high capacity, hygiene and safety. Generally used for continuous dehydration and juicing with food. In addition, screw presses can be used in waste-to-energy applications such as waste-derived fuel treatment; green applications such as waste-to-biodegradable organic waste composting; and processed commercial liquid food waste for biodiesel. Reduce the weight and volume of waste and save transportation costs.

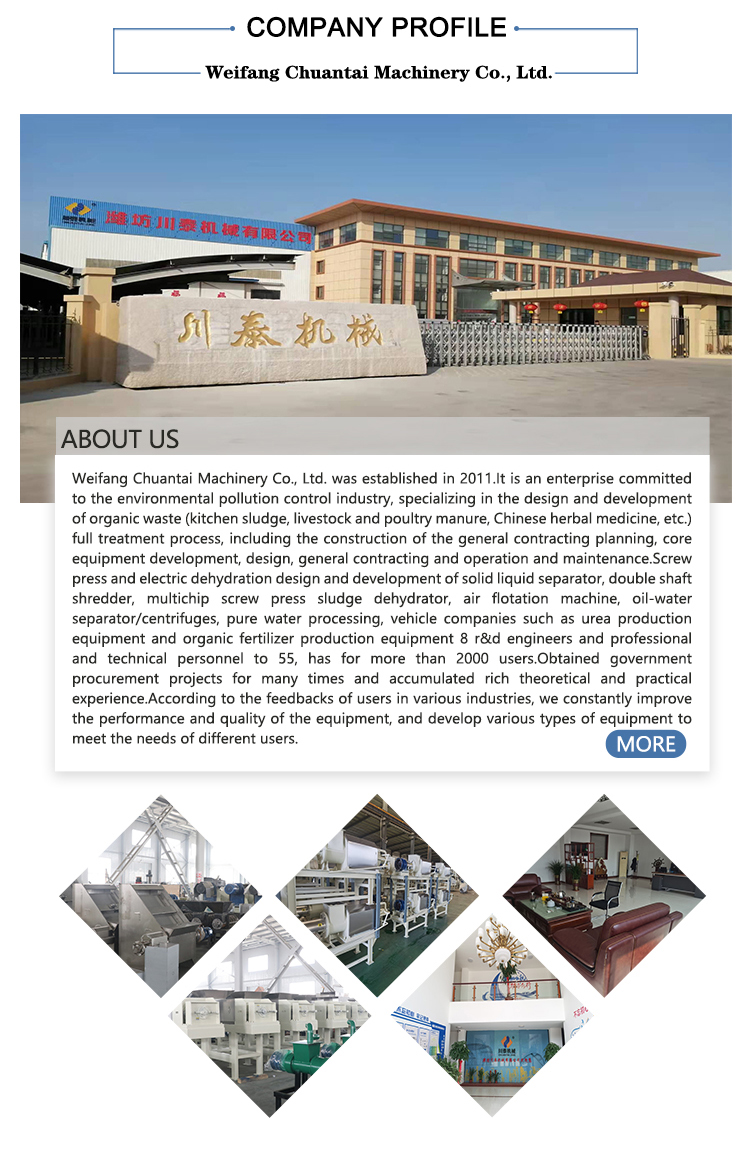

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)