The application of screw presses at this stage is becoming more and more common, especially in the fruit and vegetable pressing production and processing industry. The screw press is a dehydration equipment with better dehydration effect at the present stage. It can be squeezed step by step, without returning materials, without deviation, high efficiency, and fast drying. In addition, the screw dehydrator can not only be used as dehydration and weight reduction of waste materials or solid-liquid separation equipment for mixtures, but also can be used as juice extraction for vegetables and fruits.

The application of screw presses at this stage is becoming more and more common, especially in the fruit and vegetable pressing production and processing industry. The screw dehydrator is a dehydration equipment with better dehydration effect at the present stage. It can be squeezed step by step, without returning materials, without deviation, high efficiency, and fast drying. In addition, the screw dehydrator can not only be used as dehydration and weight reduction of waste materials or solid-liquid separation equipment for mixtures, but also can be used as juice extraction for vegetables and fruits.

The screw press is inseparable from waste water and sludge during the entire operation process. These two compounds are very harmful to the bearing. The selected bearing should be wear-resistant. In addition to the seal, the lubrication should also be in place, as follows.

1. If the bearing is found to be damaged, it should be replaced immediately. When installing new bearings, it must be specified. . Be careful not to lose it. Avoid damage to bearings and printing pressure. .split.

2. During the whole process of using mechanical equipment, pay attention to the anti-rust treatment of the bearings, and do not get too much water. Clean around the bearing seat and apply lubricant for maintenance.

The screw press is a solid-liquid separation equipment for extrusion dehydration of various waste residues composed of feed bins. .Squeezing screw type. Spiral seamless steel pipe. Slag discharge pipe and controller equipment. The slag to be processed enters the spiral seamless steel pipe from the feed bin, and is extruded and dried under the action of the extrusion screw. The water squeezed out of the raw materials is collected through the filter screen into the stainless steel sink and discharged through the sewage pipe. After the raw material becomes smaller, it is discharged through the slag discharge pipe, which greatly reduces the net weight and capacity of scale slag and other dirt. The screw press consists of a sewage pipe area, a feeding area, a screw transport area, and a feeding area. The grid slag enters the feeding area, is compacted in the compaction area by the screw press, the grid slag is discharged, and the sewage is introduced into the seepage pipe from the grid bar.

Application features of screw press:

1. The screw press is not afraid of wearing and tearing the complex materials of the biogas residue, and the water is discharged smoothly. The purpose of pressing and separating is achieved by the effective cooperation of the screw and the screen.

2. The frame screw press successfully solves the problem of screen clogging. Its patented technology is the cooperation of the screw and the screen to realize the self-cleaning function of the screen, that is, through the interaction between the special device and the screw, the material is stirred, the material axis is avoided, and the material particles are pushed forward by the screw. Wipe out clogged screen.

3. The control of the tail cone is different from the common spring, hydraulic pressure, hand wheel, etc. on the market. , adopts a pneumatic device with extremely low maintenance cost, and effectively realizes the "back pressure" control of material extrusion through specific design, that is, after setting a certain extrusion pressure, the device automatically controls the extrusion force of the material to avoid dry and wet slag and squeeze the separator Using the principle of superimposed compression, the screw compressor is especially suitable for assembly line operation, avoiding the disadvantages of centralized processing of ordinary compressors.

4. The special angle design of the feeding box of the screw press can effectively prevent the "bridging" of some viscous materials. Although the phenomenon is a small detail, once the "scaffolding" occurs on the production site, it will cause no feeding and must be shut down. Very troublesome, so the details determine success or failure.

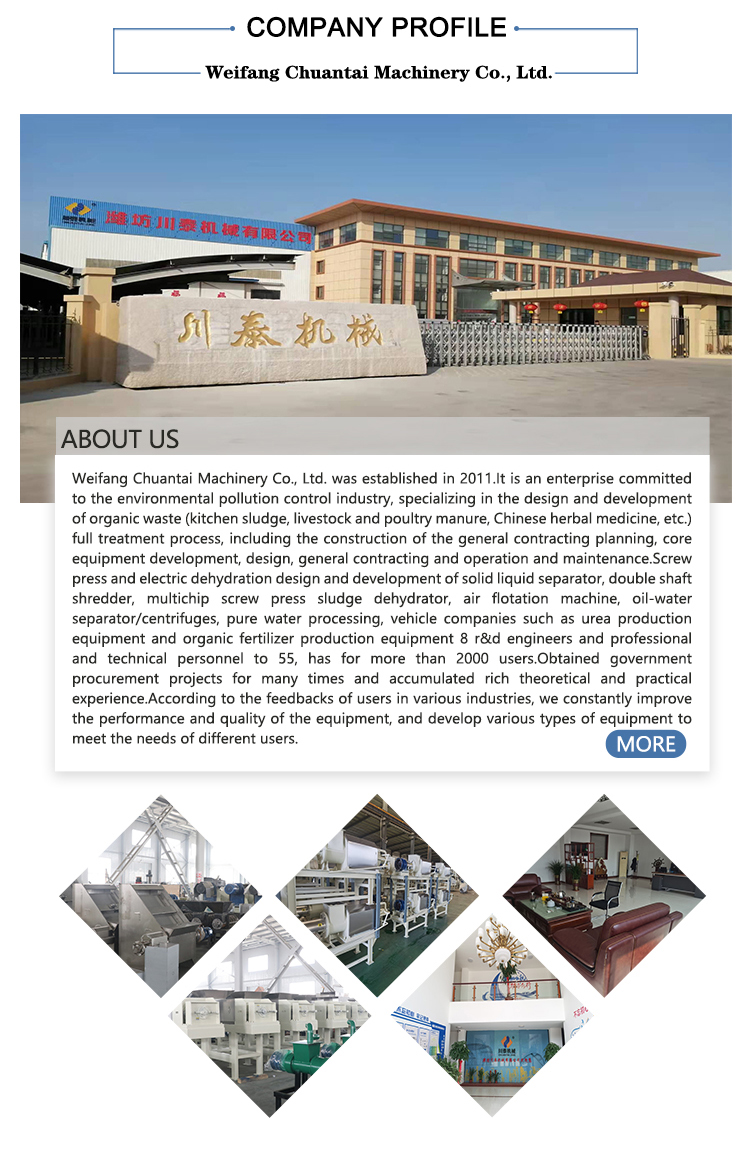

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)