How to maintain the cow dung dehydration processor?

1. The surface of the box of the mobile device should be cleared of dust and other objects. When the machine encounters unbreakable materials, it will move the bearings to the chassis, causing serious accidents.

2. When the bearing oil temperature rises, the reason for stopping and checking should be eliminated immediately.

3. If there is a knocking sound when the rotating gear is running, it should be stopped immediately to check and eliminate it.

4. The bearing bears full load in the negative machine, so good lubrication performance is closely related to the bearing life. It directly affects the service life and running speed of the cow dung dehydrator. Therefore, the injected lubricant must be clean and well sealed. Main injection points (1) Rotary bearings (2) Roller bearings (3) Full gear bearings (4) Surface bearings and sliding surfaces.

5. The newly installed chicken and cow dung dehydration motor box is easy to loosen and must be checked frequently.

6. Pay attention to whether the components of the cow dung dehydrator are operating normally.

7. Pay attention to check the wear degree of wearable parts, and replace worn parts at any time.

Main points of daily maintenance of cow dung treatment dehydrator:

1. Frequent refueling and maintenance.

The maintenance and refueling of the cow manure treatment dehydrator are very important. It is a kind of machinery, so it should be refueled and maintained regularly to avoid mechanical corrosion and internal parts aging. Add lubricating oil every 15 days to ensure the normal operation of the machine, and of course to avoid corrosion by dust and other substances.

2. Check and maintain.

The maintenance and cleaning of the cow manure processing dehydrator lies in the inspection of every detail. After a period of use, internal maintenance is required to check whether each screw and part is aging and whether there is a lack of links, so careful inspection is a necessary process to ensure the normal operation of the machine.

The cow dung treatment dehydrator has high degree of automation, low power consumption and low price. The operation is simple, just press the start and stop button to operate. The separation speed of the slag system is fast, the water content of the separated slag is between 60-70%, the slag amount and water content are adjustable, and it can be used for different feeds (such as grass and concentrated energy). It is easy to transport, and the solid content is suitable for raw materials of fish feed and organic fertilizer.

Slurry feed: Under normal circumstances, the cow manure treatment dehydrator must not start with the material. The suggestion to use this material to start the cow dung treatment dehydrator should be guided by our factory technicians.

After the cow manure processing dehydrator starts, the feeding speed should be reduced, and then increased to the required feeding speed. At the same time, the operator must be familiar with the feed control process. If the operator's skill level is low, solid liquid is solid. A common problem with skimmers is overfeeding.

Please keep in mind that since the number and speed of the screw unloaders are fixed, the discharge volume of the unloaders must not exceed the designed maximum displacement. The maximum output of the cow dung dehydrator is not determined by the unloading capacity of the screw unloader, but by the driving load and clarification (purification) capacity.

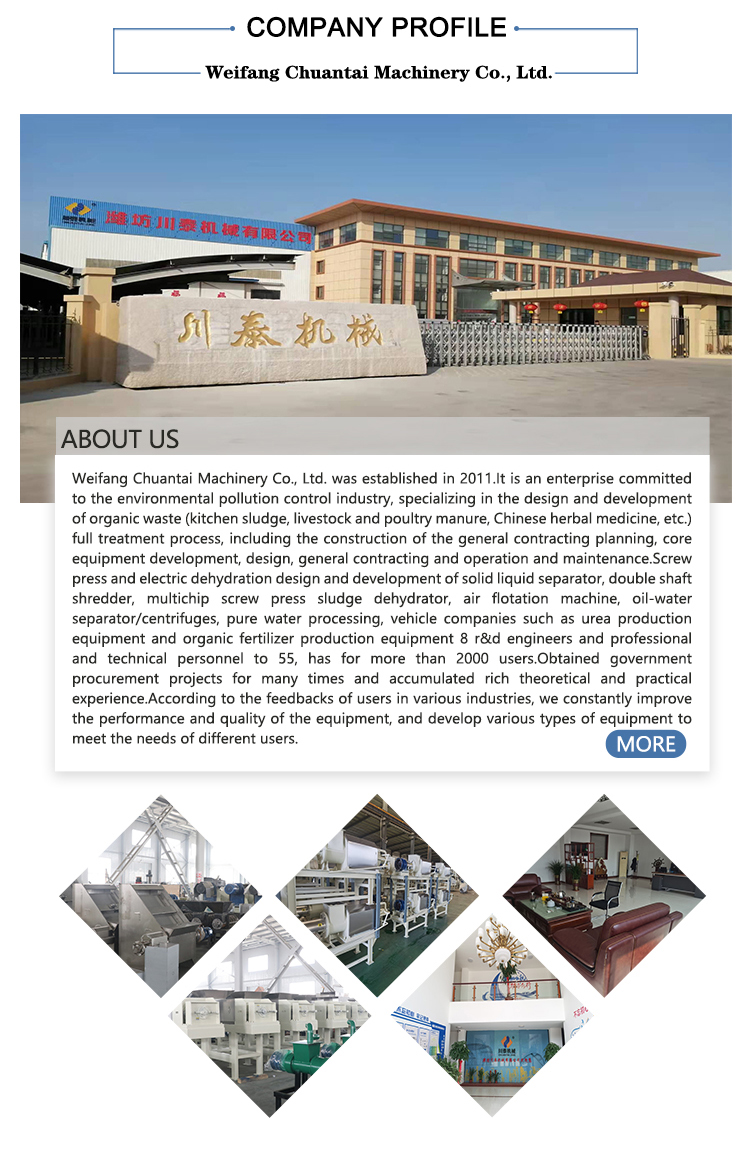

If your company wants to establish a business relationship with us, please briefly describe the cooperation intention and send an email to:chuantaiscrewpress@gmail.com

![[list:title]](/static/upload/image/20240528/1716877114510915.jpg)