screw dewatering press

Details:screw dewatering press 200screw dewatering press 300screw dewatering press 400

screw dewatering press 200

screw dewatering press 300

screw dewatering press 400

Chuantai Machinery Screw Press Technical Parameters

Weifang chuantai Machinery Co., Ltd.

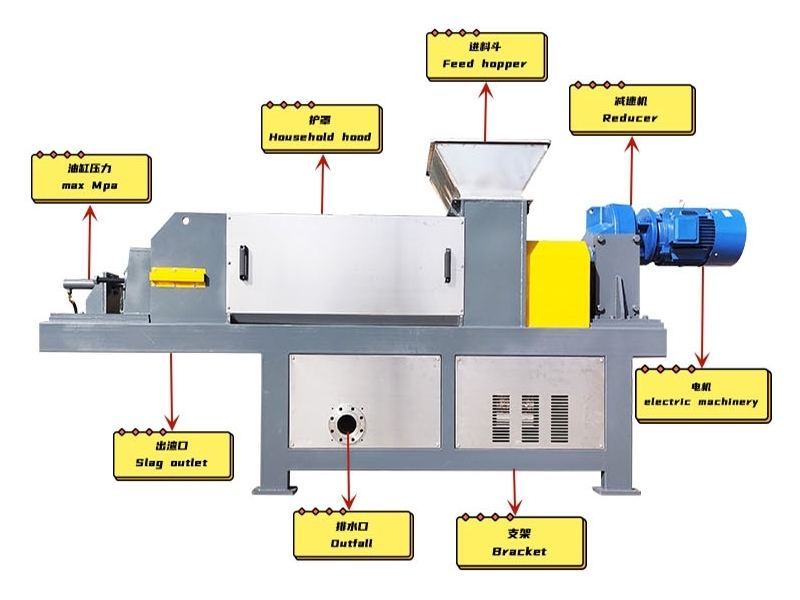

1. Equipment introduction

Screw press is a kind of equipment that uses physical extrusion to dehydrate. The material box enters the equipment and is squeezed step by step under the conveying of the screw auger. The excess water is discharged from the liquid outlet through the screen. The discharge port discharges the equipment. The screw press produced by our company has undergone hundreds of accurate theoretical derivation calculations and experimental tests, summed up the real effect feedback of many users in the process of using it for many years, and upgraded it to a series of mature equipment in an all-round way. Different technical parameters can truly achieve low energy consumption, high output, and low moisture, saving a lot of processing costs for the secondary recycling of materials.

2. Working principle

The dehydration process of the screw press dehydrator is divided into two stages. In the first stage, the screw auger is used for dehydration. The screw auger is divided into three sections: the transmission section, the compression section and the discharge section. The transmission section ensures that the material enters the equipment smoothly. As the transmission space becomes smaller step by step, the pressure on the material increases step by step, forcing the volume of the material to shrink and squeeze out the water; the second stage uses the blocking device to dehydrate, when the material enters the discharge section of the auger, the auger The auger will exert an axial thrust on the material to push it out of the outlet, and at the same time, the material blocking device pressurized by the air pressure device will exert a reverse force on the material to be pushed out, thereby forming an extrusion force to dehydrate the material in two stages .

3. Equipment Features

3.1. Low operating cost

The screw press adopts the principle of physical extrusion dehydration, no additional heat source is required during the dehydration process, and the energy consumption is extremely low compared with similar drying equipment.

3.2. Large amount of continuous work processing

The parameters of the screw auger have been calculated and analyzed by mechanics, and the axial thrust is increased by using special technology, which completely solves the problems of non-continuous work caused by slipping, bridging, returning materials, reporting shafts and other reasons, and the processing capacity per unit time is greatly increased.

3.3 Low moisture in slag

Due to the wide variety of materials to be dehydrated, the moisture content, molecular water ratio, viscosity, fiber content, water absorption, toughness, organic or inorganic materials of different materials are different. Analyze the dehydrated material, calculate the parameters suitable for the material, make suitable equipment, make the best use of the physical pressing effect, and reduce the moisture content of the extruded material.

3.4 Wear resistance and corrosion resistance

The key parts of the screw press are sprayed with a wear-resistant layer, and a layer of alloy cutter head is welded on the surface of the screw auger blade to increase wear resistance; the core components are made of 304 stainless steel, which is resistant to acid, alkali and corrosion, thus greatly extending the service life of the equipment.

3.5. No need to add medicine

A screen with a gap of 0.3mm-1.0mm can be selected according to the properties of the material to be dehydrated. There is no need to add flocculant and other agents during the dehydration process, so there is no need to increase the cost, and at the same time, the secondary use of the material will not be affected by the addition of chemical components.

Weifang chuantai Machinery Co., Ltd.

contact:Manager Liu

mobile:+86 13053656336

email:Mr.liu@mantsen.net

address:Weifang City, Shandong Province,China