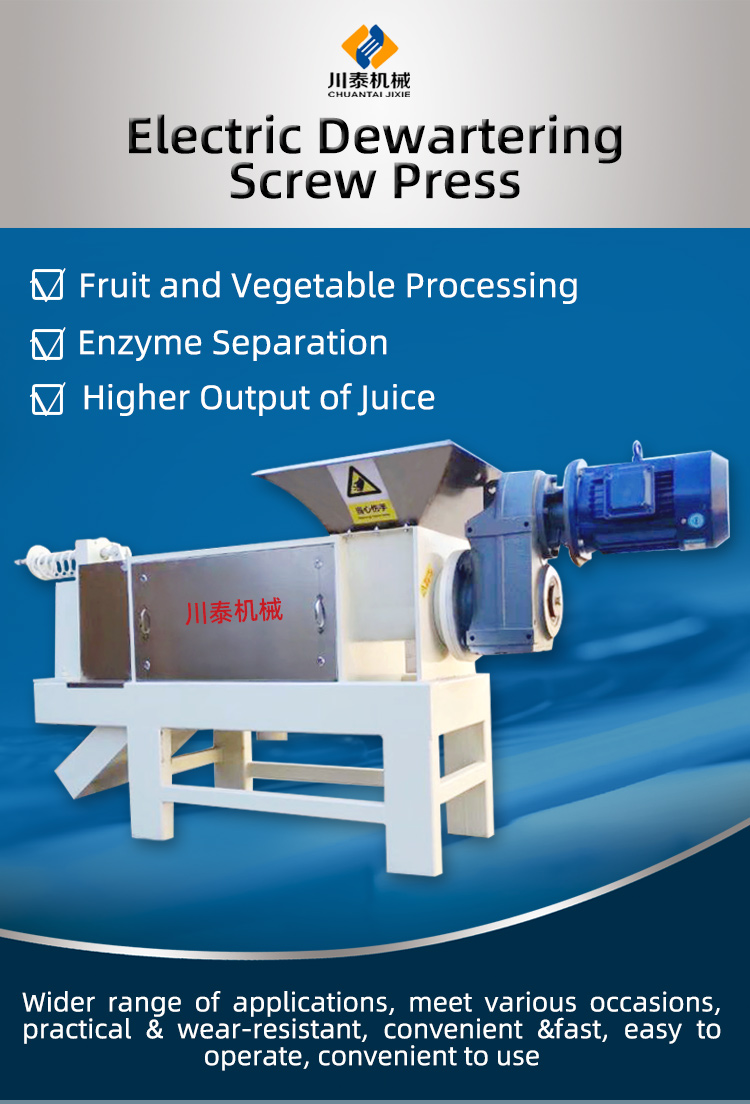

DEWATERING SCREW PRESS

Details:DEWATERING SCREW PRESS Technical Parameters of Chuantai Machinery Screw Press一、设备介绍1. Equipment introduction螺旋压榨机是一种利用物理挤压方式进行脱水的设备,该设备由驱动系统、进料箱、螺旋绞龙、筛···

Technical Parameters of Chuantai Machinery Screw Press

一、设备介绍

1. Equipment introduction

螺旋压榨机是一种利用物理挤压方式进行脱水的设备,该设备由驱动系统、进料箱、螺旋绞龙、筛网、气动阻料装置、集水槽、机架等部分构成,物料从进料箱进入设备,在螺旋绞龙的输送下受到逐级递进压力挤压,多余水分经过筛网由出液口排出,去水分物料在螺旋绞龙的继续输送下,顶开阻料装置由出料口排出设备。我公司所生产螺旋压榨机经过数百次精确理论推导计算和实验检验,总结众多用户在多年使用过程中的真实效果反馈,全面升级为一系列成熟设备,对客户不同待脱水物料精确分析,采用不同技术参数,真正做到低能耗、高产出、低水分,为物料进行二次循环利用节省大量加工成本。

The screw press is a kind of equipment that uses physical extrusion to dewater. The material box enters the equipment and is squeezed by the progressive pressure under the conveying of the screw auger. The excess water is discharged from the liquid outlet through the screen. Under the continuous conveying of the screw auger, the top-opening resistance material device is discharged from the liquid outlet. The discharge port discharges the equipment. The screw press produced by our company has undergone hundreds of accurate theoretical derivation calculations and experimental tests, summed up the real effect feedback of many users in the course of many years of use, and has been fully upgraded to a series of mature equipment. Different technical parameters can truly achieve low energy consumption, high output, and low moisture, saving a lot of processing costs for the secondary recycling of materials.

二、工作原理

2. Working principle

螺旋压榨脱水机的脱水过程分两个阶段。第一阶段利用螺旋绞龙脱水,螺旋绞龙分传输段、压缩段和出料段三段,传输段保证物料平稳进入设备,脱水段螺旋叶片螺距和螺旋内径逐级变小,从而传输空间逐级变小,由于传输空间的逐级变小对物料形成逐级增大的压力,强制物料体积缩小压榨出水分;第二阶段利用阻料装置脱水,当物料进入螺旋绞龙出料段,螺旋绞龙会对物料施加轴向推力将其推出出料口,同时由气压装置加压的阻料装置会对即将被推出的物料施加反向作用力,从而形成挤压力对物料进行二阶段脱水。

The dehydration process of the screw press dehydrator is divided into two stages. In the first stage, the screw auger is used for dehydration. The screw auger is divided into three sections: the transmission section, the compression section and the discharge section. The transmission section ensures that the material enters the equipment smoothly. The stage becomes smaller, due to the gradual reduction of the transmission space, the pressure is gradually increased on the material, forcing the volume of the material to shrink to squeeze out the water; the second stage uses the material blocking device to dehydrate, when the material enters the spiral auger discharge section, the spiral The auger will apply axial thrust to the material to push it out of the discharge port, and at the same time, the material blocking device pressurized by the air pressure device will exert a reverse force on the material to be pushed out, thereby forming a squeezing force for two-stage dehydration of the material.

三、设备特点

3. Equipment Features

1、运行成本低

1. Low operating cost

螺旋压榨机采用物理挤压脱水原理,脱水过程中无需额外提供热源,相比同类烘干设备耗能极低。

The screw press adopts the principle of physical extrusion dehydration, no additional heat source is required during the dehydration process, and the energy consumption is extremely low compared with similar drying equipment.

2、持续工作处理量大

2. Large amount of continuous work processing

螺旋绞龙的参数经过力学计算分析,利用特殊工艺来增大轴向推力,彻底解决打滑、架桥、返料、报轴等原因导致无法持续工作的问题,单位时间内处理量大大增加。

The parameters of the screw auger are analyzed by mechanical calculation, and the axial thrust is increased by using a special process.

3、出渣水分低

3. Low slag moisture

由于待脱水物料种类繁多,不同物料的含水率、分子水比例、粘度、纤维含量、吸水性、韧性、有机物或无机物等等数据各有不同,我公司工程师会根据每一位客户提供的待脱水的物料进行分析,计算出适用于该物料的参数,制作出适合的设备,将物理压榨作用利用到极致,降低挤出物料含水率。

Due to the wide variety of materials to be dehydrated, the moisture content, molecular water ratio, viscosity, fiber content, water absorption, toughness, organic or inorganic materials of different materials are different. The dehydrated material is analyzed, the parameters suitable for the material are calculated, and suitable equipment is made to make the best use of the physical pressing effect and reduce the moisture content of the extruded material.

4、耐磨耐腐蚀

4. Wear and corrosion resistance

螺旋压榨机关键部位喷涂耐磨层,螺旋绞龙叶片表面加焊一层合金刀头,增加耐磨性;核心部件采用304不锈钢制作,耐酸耐碱耐腐蚀,从而大大延长设备使用寿命。

The key parts of the screw press are sprayed with a wear-resistant layer, and a layer of alloy cutter head is welded on the surface of the spiral auger blade to increase the wear resistance; the core components are made of 304 stainless steel, which is resistant to acid, alkali and corrosion, thus greatly extending the service life of the equipment.

5、无需添加药剂

5. No need to add drugs

可根据待脱水物料性质选择0.3mm-1.0mm间隙的筛网,脱水过程无需添加絮凝剂等药剂,故无需额外增加成本,同时不会因加入化学成分影响物料二次利用。

Screens with a gap of 0.3mm-1.0mm can be selected according to the properties of the materials to be dehydrated. There is no need to add flocculants and other agents during the dehydration process, so there is no additional cost, and the addition of chemical components will not affect the secondary utilization of materials.